Attention to the customer for greater product/service quality

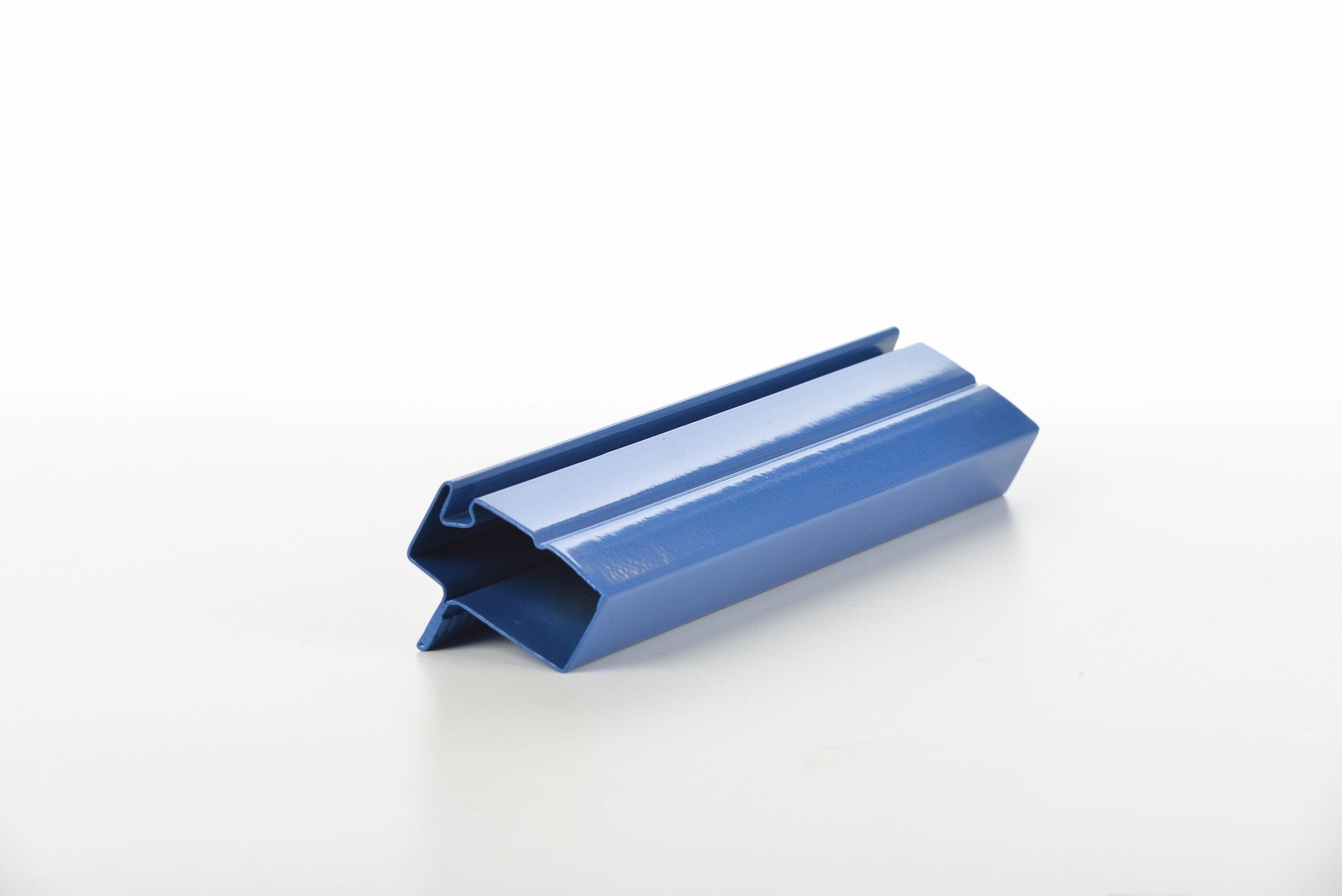

Search for the best solutions to develop the product based on customer requests and needs.

Design, manufacture and maintenance

of lines and systems for industrial automation

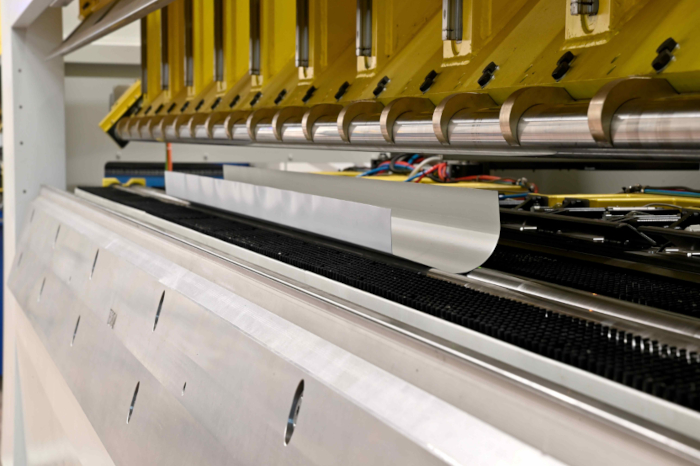

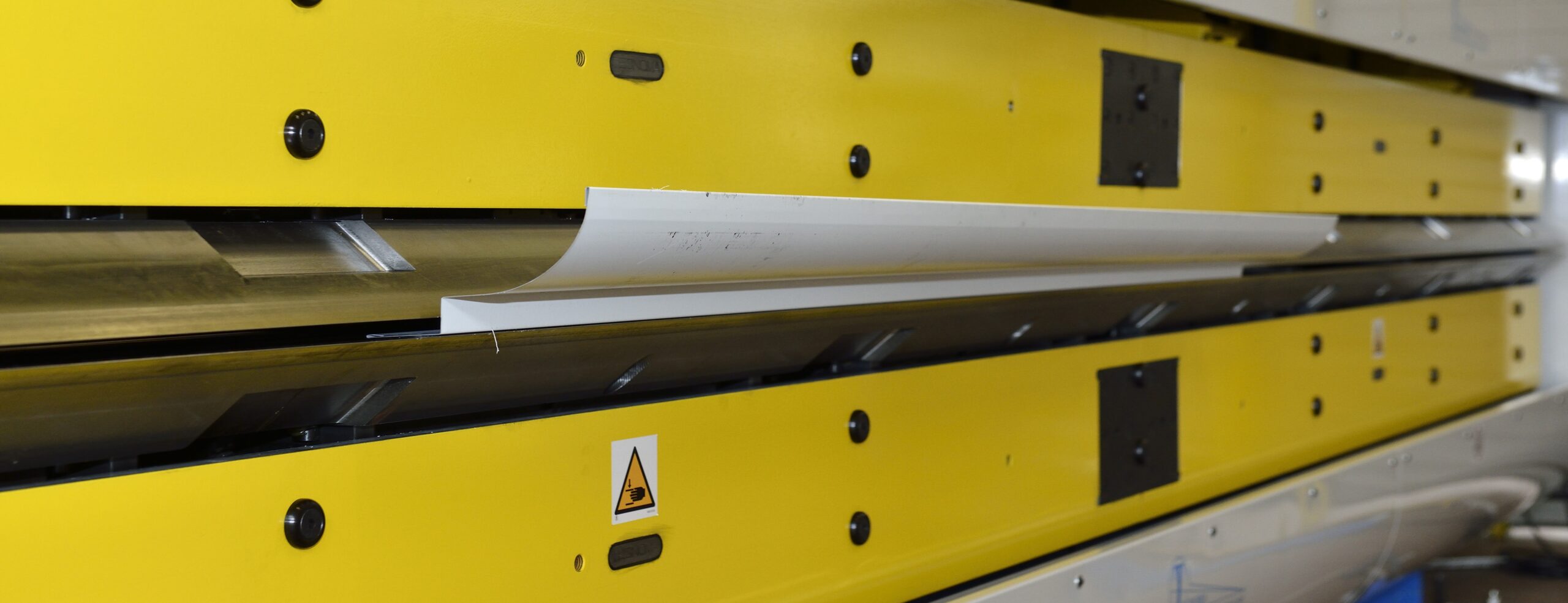

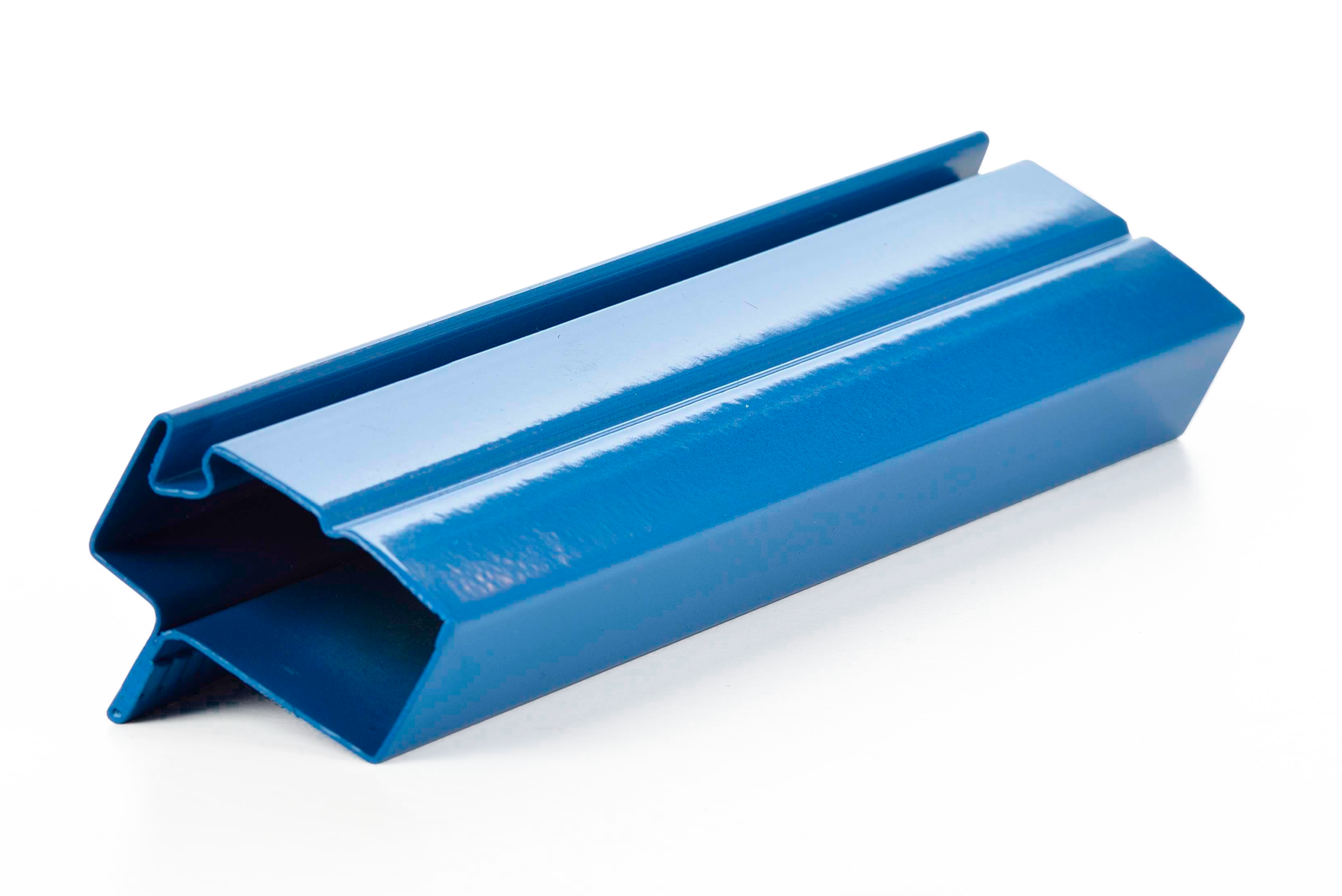

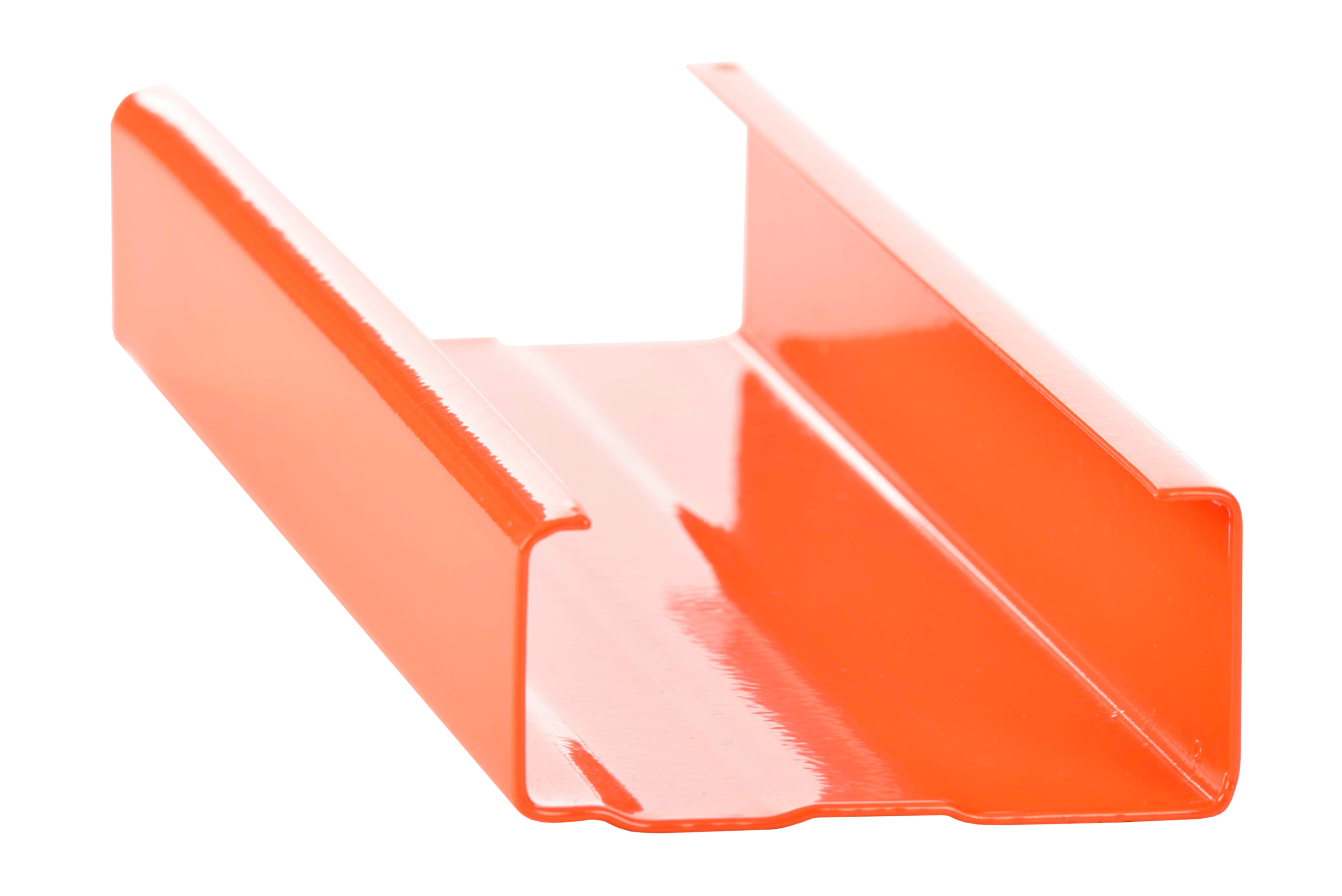

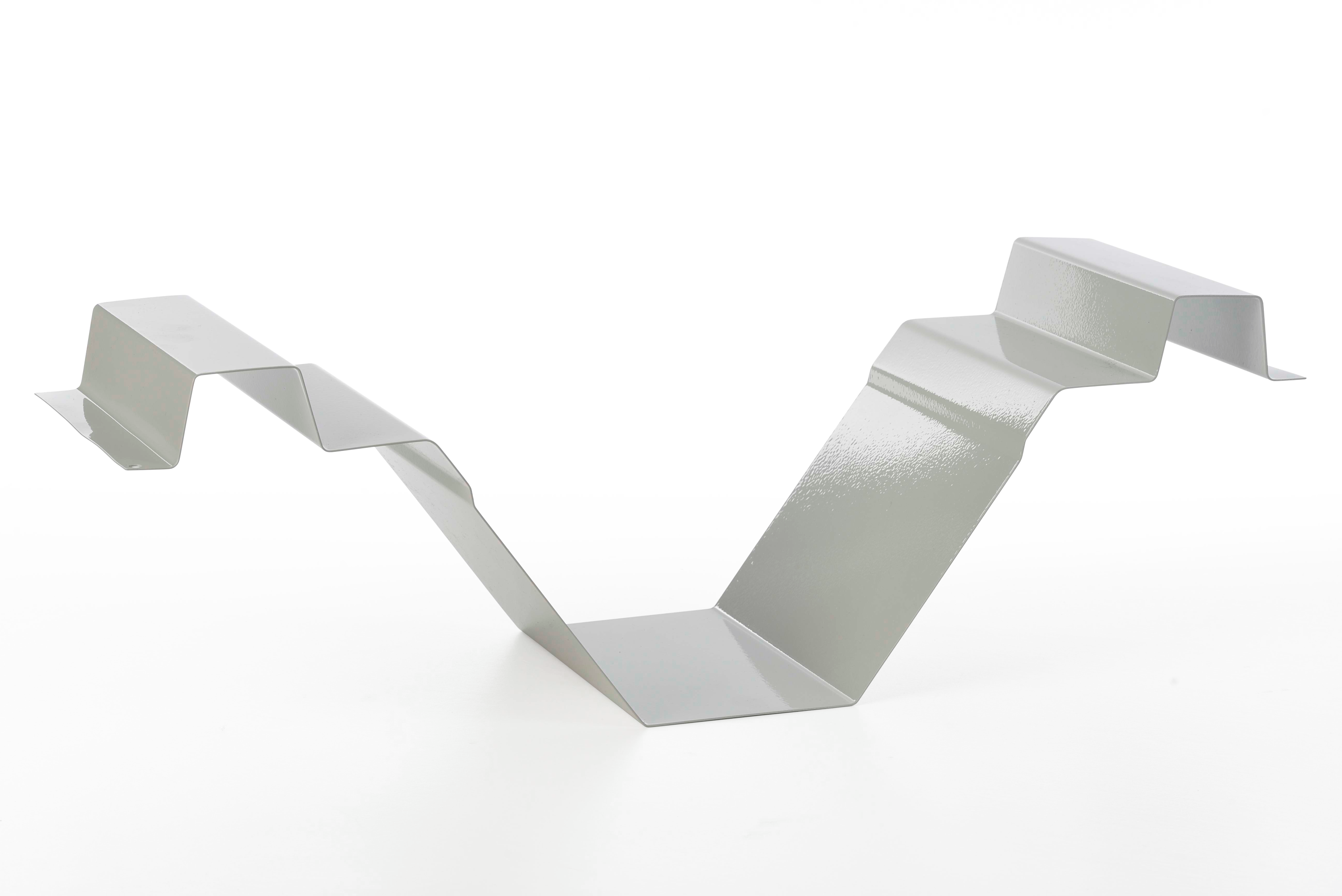

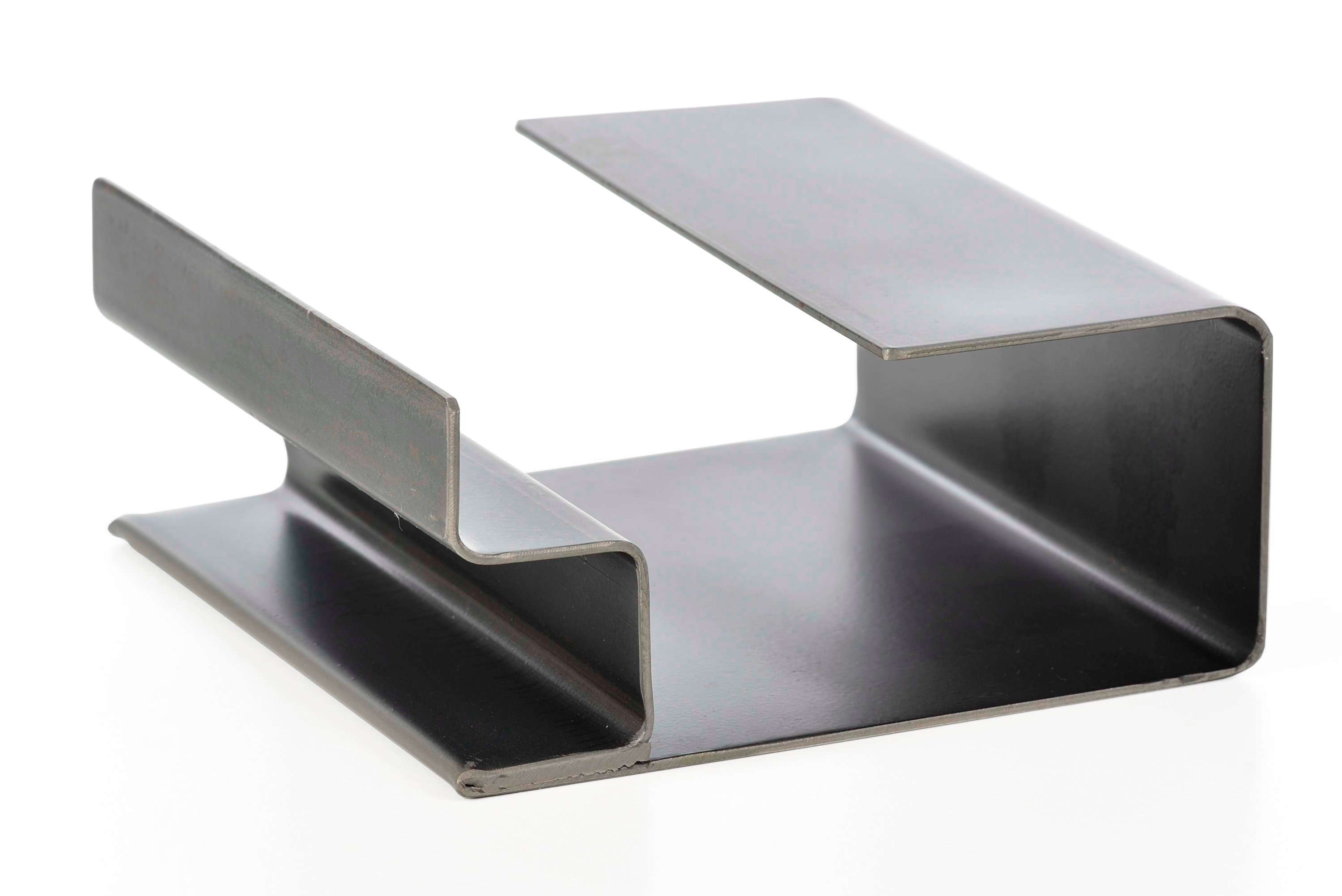

Tecnoma, since 1994, has specialised in the design and construction of roll forming lines, from the introduction of the sheet metal to the packaging of the finished product. Our long experience allows us to follow the customer through all the stages of the project: from the study of the profile to the design and realisation of the plant. We guarantee personalised technical support and consistently high quality standards. Recognised as a ‘quality manufacturer’, TECNOMA now has a worldwide reputation in the field of roll forming. Our products meet the professional requirements of our customers, both in terms of quality and environmental compatibility, guaranteeing precision and reliability.

GREEN sheet metal processing

II our goal today is to make all our machines and all-electric for reasons of safety and environmental sustainability in an overall GREEN framework.

Indeed, the sheet metal working industry is experiencing a momentous transformation thanks to digitalization. For Tecnoma, Industry 4.0 has been a turning point, introducing digital technologies into the field of mechanics to put it to optimize production processes and improve the overall efficiency of its machines.

Thanks to machine connectivity, it has become possible today to monitor machine performance and optimize production through data analysis.

Digitization is revolutionizing sheet metal working, introducing new technologies and production models that radically transform the industry. From Industry 4.0 to the 5.0 Transition Plan, Tecnoma walks the road to a more efficient, sustainable and safe future .